Looking back in the past years of research on the topic of sustainable product design, one can say that the international research community and the industry succeeded in building specific competences required for reaching more sustainable manufacturing. There have been large research efforts for measuring the environmental impact of products and processes. Public institutions and industrial sectors also performed great achievements in setting up specific environmental management strategies such as product end-of-life take back and processing (a big thing in the 90’s, particularly concerning cars and electronic scrap), energy efficiency of energy using products (a big thing in the years 2000, especially due to the European directive on energy using products) and energy efficiency of manufacturing systems.

But these successful stories are not that much related to product design and good examples of successfully eco-designed (where “eco” refers to the environment) products are still scarce. Or at least: the current eco-design practices still fail reaching more than marginal environmental impact reductions where drastic reductions are required.

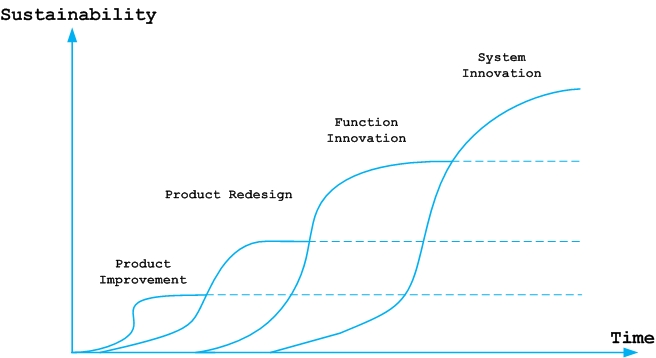

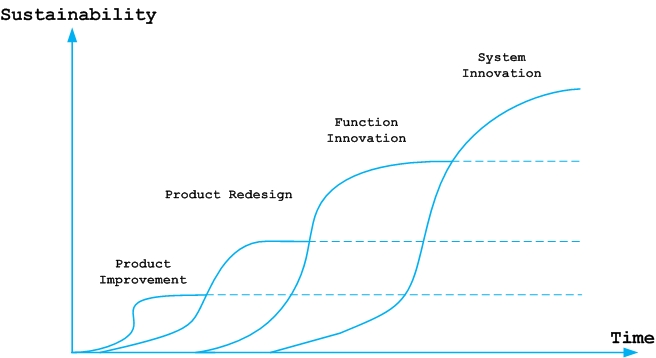

To give a simple picture of what I mean: as I first learned about eco-design almost ten years ago, I saw this beautiful simplistic figure [1]:

Basically, it says four things:

- There are basically four levels of innovation: product improvement, product redesign, function innovation, system innovation.

- The higher the level, the better it is for sustainability. Product improvement may help you saving 10% environmental impacts while system innovation may lead to drastic decoupling between the social value of a product and its environmental impacts.

- It takes time and effort to come to the highest levels.

- But there is hope: it seems that we can reach the higher level someday. At least this layer exists, it is on the figure!

Looking back in the elapsed time since I first saw this figure, I have the feeling we got stuck at the first level—that we got good at improving details but are still unable to reach significant innovations. And indeed, a systematic consideration of environmental aspects as a driver of industrial or engineering design hasn’t been reached yet. Some of our colleagues from said it in 2002 already [2], years before I even started making research in eco-design: „the problem nowadays is not the lack of methodological support in product design, rather that of choosing the most suitable method from the many methods now available“. So if we have a lot of methods helping us to consider the environment into design, why don’t we use them? Where is the trick?

The problem of getting the industry using these methods still keeps researchers busy today [3]. But I don’t have the feeling we are getting much closer with the time. The social structures in which products take place put too many constraints to design. Meeting high levels of eco-innovation means breaking with conventional business models, production and consumption patterns. Many people dealing with eco-design acknowledge this and may have hoped of a massive evolution of these constraints that did not happen. Businesses in companies did not changed that much and are still based on selling stuff, the GDP (i.e. the value of all stuff sold) is still the most used macroeconomic indicator and social status of individuals is still measured by the amount of stuff they have. Engineers did their jobs in developing practical approaches to develop eco-designed products that remain unused because the underlying organisational changes did not really happened, or happen too slowly.

At this point, there are two possibilities. Either keep going on struggling with the existing constraints and advocating in the desert. Or look for alternatives design concepts that tend to challenge these constraints. In my opinion, open source hardware [5] is one of these alternative ways of developing products that bears the potential of breaking the barriers applying to ecodesign. Because it tends to challenge the way goods are produced and consumed. Here are my hypotheses.

First, the concept of open source puts the emphasis on making, on “doing” instead of “having”. It is not about how much things you own, it is about what you make. That is, it promotes a vision of social status decoupled from consumption, what may lead to reduced consumption volumes. Moreover, the direct participation of the user in the design may lead to better fitting products and to the avoidance of over-engineering and of the corresponding useless environmental impacts.

Second, open source hardware is at the opposite of intentional planned obsolescence. Because it reclaims the independence of the citizen from technology, it tends to promote repairable product design and actual capability building in repairing products. Many open source hardware projects pay for example attention to modularity. Modularity is an enabler of maintainability, repairability, upgradability, reusability and recyclability, and in turn supports product longevity. The intensified emotional link between the product and the user (the “I made it by myself”-effect) may also contribute to longer service lives and therefore to reduced environmental impact per unit of service.

Third, open source hardware promotes the participation of the citizen not only in the design but also in the production, under the motto “design global, produce local” [6]. This may lead to locally bound value creation chains, use of local resources, shorter transportation loops, adaptation to the local ecosystems and even closed loop material cycles. Many open source hardware projects strive to design products using local material flows (motto “design with what you have”) or simple products that can be fabricated within conventional workshops.

These are of course only hypotheses. Who can say today if the possibility for everybody to design and produce his/her own products will contribute to frugal and utilitarian consumption or to overabundance of recreational gadgets? Who can say if the potential economies of scopes achieved by local production (produce less) won’t be overwhelmed by the lack of economies of scale (as personal production may be far less efficient than centralized industrial production). But I have the strong feeling that open source hardware is a good way to promote sustainable production and consumption offers a good workaround to the constraints applying to product design.

Here are some questions that can be addressed today and that may deliver partial answers:

- What is local production and under which conditions is it better than mass production?

- Given the unavoidable limitations in terms of skills, materials and machines, what quality range of product quality is accessible in local production?

- How to support a sustainable local manufacturing, i.e. in designing product that are adapted to the locally available materials, machines and skills but also to the local needs?

This is a transcription of a talk I gave at the 3rd International conference on Sustainable Design and Manufacturing.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

[1] Brezet, H. (1997). Dynamics in ecodesign practice. Industry and Environment, 20(1-2), 21-24. Reworkerd by İdil Gaziulusoy. https://systeminnovationforsustainability.com/about/

[2] Ernzer, M., and H. Birkhofer, eds. 2002. Selecting methods for life cycle design based on the needs of a company.

[3] Pigosso, Daniela C. A., Henrique Rozenfeld, and Tim C. McAloone. “Ecodesign Maturity Model: A Management Framework to Support Ecodesign Implementation into Manufacturing Companies.” Journal of Cleaner Production 59 (November 15, 2013): 160–73. doi:10.1016/j.jclepro.2013.06.040.

[5] A definition of the term “open source hardware” is available here. This concept can be alternatively termed as „open design“, following for example here.

[6] Kostakis, Vasilis, Vasilis Niaros, George Dafermos, and Michel Bauwens. “Design Global, Manufacture Local: Exploring the Contours of an Emerging Productive Model.” Futures 73 (October 2015): 126–35. doi:10.1016/j.futures.2015.09.001.